Milk farmers could soon begin earning extra money if their milk contains more fat and is clean, the Ministry of Agriculture proposes in a draft law.

Currently, farmers are paid just per litre of milk supplied.

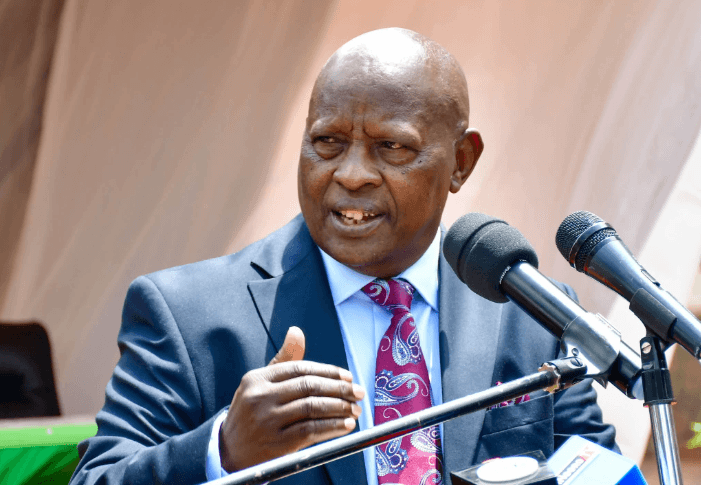

But, State Department for Livestock Development PS Jonathan Mueke says this system is outdated.

He said the standard globally is to pay farmers based on both quantity and quality.

“If only the quantity payment is used, milk producers may adulterate the pure milk such as by adding water so they can get more money for their milk,” he said. “So we are moving to quality-based payment where we will pay in regards to how much butterfat is in your milk, how much protein is in your milk, how much solids are in your milk.”

Fat in the milk is used to manufacture high value dairy products such as yogurt, cheese, butter, ghee and cream.

“So right now we pay them Sh50 per litre; if they bring good quality that can make high value items, then we may pay Sh60. What that does is it incentivises the farmer to produce high quality milk,” he said in an interview with the Star.

The proposal is contained in the draft Dairy Industry Bill 2024.

Mueke said the current Act that regulates milk trade in Kenya is from 1957. “So the Dairy Industry Bill 2024 is updating all the realities today. It's to ensure that we can regulate the dairy industry properly, we can promote milk consumption, we can promote milk trade, we can promote milk safety,” he said.

With the quality based payment, a farmer earns extra money based on good appearance and taste of the milk, cleanliness, fat content.

The ministry, Bio Foods Products Limited and Usaid are currently running a 'Safe Milk Kenya' campaign to help farmers produce high-quality, safe milk for local and export markets.

The campaign, launched in January this year, also has other initiatives to foster growth within the dairy industry.

Mueke said they are targeting the entire dairy value chain from feed manufacturers, farmers, milk processors and consumers.

He encouraged Kenyans to buy only processed milk because processors are able to test and reject milk contaminated with bacteria such as aflatoxin.

He said some of those contaminants cannot be eliminated by boiling or pasteurisation.

“Boiling the milk will not get rid of things like aflatoxin, which comes from the animal feed that the cow ate. Aflatoxin causes stunted growth in children, it causes cancer in human beings. So we need to ensure that any aflatoxin laced milk doesn't even make it to the consumer, it gets discarded at source because once it's in the milk, there's no way to get rid of it,” he said.

The PS said most milk producers in Kenya are small scale and maybe unable to afford the technology to test such contamination.

“So we are also telling the consumers, watch out for your own health and for your own safety. Buy products that are tested, that are certified as good for human consumption” he said.

The PS noted that farm gate milk is likely to be contaminated if the farmer used dirty hands, the cow was treated with antibiotics and was milked within 48 hours or if the cow was given feed with aflatoxin among others.

He said 65 per cent of Kenyan milk is sold at the farm gate and only 35 per cent is processed.

The 'Safe Milk Kenya' project is an end-to-end value chain oriented campaign, that seeks to reduce aflatoxin contamination in the Kenyan dairy ecosystem.

"I am very passionate about agriculture and smallholder farmers. The partnership is between us and Bio Foods, not just about business. We intend to ensure every Kenyan has access to safe food," US ambassador Meg Whitman said during the launch in January.

"We will equip farmers with techniques and tools to produce safe dairy products."

Aflatoxin contamination of milk has become a major problem in the dairy industry.

It has led to the reduction of animal productivity, causing animal death and exposing consumers to a high risk of terminal illnesses including cancer and in some cases death.