The government is doing a campaign to promote safe production and consumption of milk.

The campaign came up due to the continuing prevalence of dangerous mycotoxins, the most common aflatoxin in food and dairy.

The initiative advocates best practices in the entire value chain from the farm to the table.

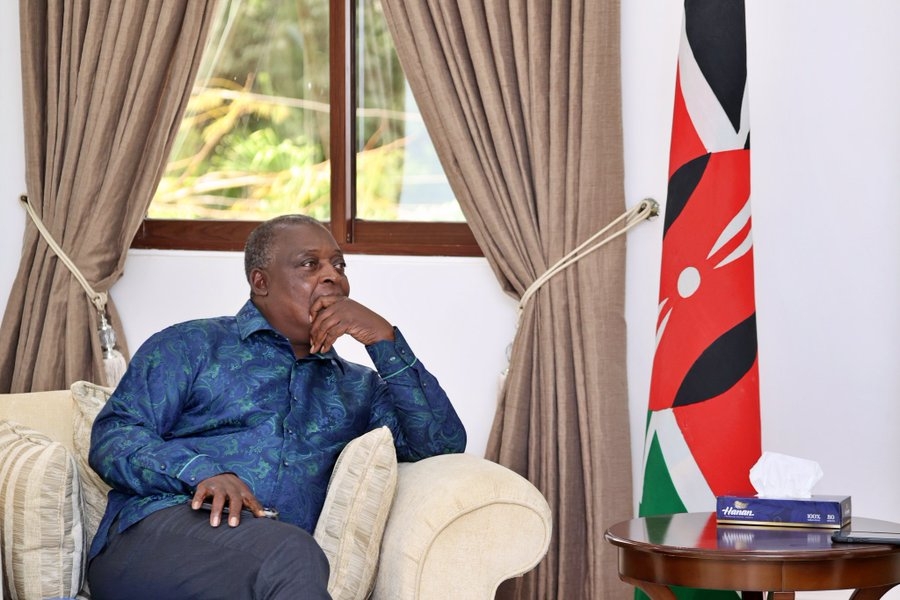

Bio Foods CEO Joachim Westerveld spoke to the Star on the role his company is playing.

Tell us briefly about Bio Foods.

Bio Foods is one of the leading dairy processors in Kenya. We produce dairy products on the most global and highest quality standards. We work with farmers to ensure we get quality milk and in return, pay them the best prices in the market.

If you want to grow your dairy processes, you need to make sure that your farmers are actually profitable and growing. After getting clean and healthy milk, we then process it into various dairy products that people love. We were the first one in 1992 to introduce fruit yoghurts in Kenya and in 2016, we launched fresh milk.

What informed the founding of Bio Foods?

The company was started by Binoy Zachariah. In 1989, Binoy was on a flight from Nairobi to Turi with Swiss Air. While on the flight, he got some Muller fruit yoghurt. Muller is a very high-quality fruit yoghurt in Switzerland. So he tasted the yoghurt and said he needed to bring it to Kenya. In 1992, in Langata, Binoy started buying food products based on the idea of bringing high-quality fruit yoghurt to Kenya.

He started with nine people. It’s very nice to know that now, so many years later, we still have three of these nine working for us in the business. Based on that, Binoy recruited a Swiss quality manager and together, they laid the foundation of Bio Foods.

The whole idea was to take the best quality milk and best quality fruits. Today, we have more products, and we're a lot bigger, but the philosophy still doesn't change.

How different is Bio Foods, and what makes the company stand out?

We're now in modern trade and one of the market leaders in terms of fresh milk. Over the last couple of years, we have had a lot of innovations, including Greek-style yoghurt that people love. We are a company that tries to delight our consumers by giving them the best-tasting, healthiest and cleanest dairy products.

We try to delight our farmers by paying them good prices, giving them a little support and making sure they produce a lot of very high-quality milk so that they can make good money.

You talked about how you work with dairy farmers. How does that partnership work?

We do a couple of things to ensure that as a company, we remain afloat through quality supplies from our farmers. One of the things we do is that we have very stringent quality norms. We also pay the best prices. For instance, in the market, the price is anywhere between Sh40 and a maximum of Sh55. We pay up to between Sh58 and Sh65, based on quality parameters. This is an incentive for farmers.

We also support farmers with their developments. That means we spend a lot of time with the farmers actually making sure that they produce more quality milk. We also help farmers with feed advice, health management and herd management and advise them on shifts and farm practices. We also try to create an ecosystem around them by helping them with financing and choice of animal feeds.

What we have experienced in Kenya in the last two years is the shilling weakening and input costs going up. If the farmer is not profitable, and not successful, we can’t grow.

Partnerships often come with their fair share of challenges. Is this one bearing fruit?

We look at profitability by running a margin after feed cost analysis every month. In this, we are able to see the input costs. The global norm is that for a farmer to be successful, one needs to be able to make a 35 per cent margin after feed in their pocket.

On a monthly basis, we look at the input cost. What we have experienced in Kenya in the last two years is the shilling weakening and input costs going up. So we adjust our milk price based on that cost. Because if we see that our input costs have gone up, and they cannot make that 35 per cent margin, we first look at the problem on the farm. If it's a general norm, if it's a general trend, then we adjust our pricing to make sure that they can make a profit. If the farmer is not profitable, and not successful, we can’t grow.

Now that you have partnered with USAid under the Safe Milk Kenya project, how will this initiative enhance the safety of dairy products?

The partnership with USAid is geared towards creating a coalition with farmers, other processors, feed manufacturers and the consumer together to make sure we have better milk in Kenya. It is a systemic issue and there's no malice in the system. We're very grateful for the partnership we have with USAid and also with the Kenya Dairy Board and the Ministry of Agriculture in the Department of Livestock.

We want to see how we can bring all the stakeholders together to start improving the practices on the farm. This means that we improve the practices with the dairy process in the feed producers, keep the milk safe and inform the consumer about safe milk. If you train farmers, they can make choices, and they can start asking questions to feed suppliers and tell them to give them a certificate of analysis that shows that the feeds are free of aflatoxin. It takes a coalition of partnerships to build a robust dairy sector.

We're going to sensitise 10 million Kenyan consumers about safe milk. We're going to train 5,000 farmers

How long will the Safe Milk Kenya campaign last?

This project should continue forever. We have been doing the campaign for the last 30-plus years. The project will be about one and a half years. We're going to sensitise 10 million Kenyan consumers about safe milk. We're going to train 5,000 farmers.

That's only the start because we believe that with the partnership, we will start a movement that, as a nation, we're going to move in the direction of focusing much more on the quality of dairy products. I think there's also a new dairy bill and quality-based pricing is going to be implemented in Kenya.

This initiative shows that this administration is very committed to milk quality. The project is one and a half years but I think the journey will continue afterwards.

When is milk considered unsafe for human consumption?

Milk is intrinsically very healthy, with calcium and vitamins, and very nutritious for good general energy and strong bones. I think what happens is at certain times, there's contamination.

So milk gets contaminated in a couple of ways. So first is hygiene. If the milk is milked and stored in contaminated cans, there will be bacterial contamination. When milk comes out of the cow, it's at about 37 degrees. If you don't treat it for a long time and the environment is not clean, that milk is going to germinate, which means the bacterial load will increase.

The second is antibiotics. So if a cow is treated with antibiotics, that milk should be separated because that milk will contain antibiotics. If you ingest antibiotics, small doses of antibiotics to milk and other products every day, you're going to become antibiotic resistant.

How do animal feeds affect the quality of milk? Any threats as well to human beings?

When feeds are further stored at too high a moisture content, there's mould. Then there is toxic produce, which is called aflatoxin, and aflatoxin is highly cancerous. So when you feed your cows with feed or fodder that has aflatoxin, the milk will contain aflatoxin.

Aflatoxin comes to us through milk, but also for instance, through maize. If maize is stored at too high a moisture content, there is aflatoxin, which also comes in meat. So long-term ingestion of small doses, right to high doses of aflatoxin, will lead to a higher chance of cancer. It is not something you can feel today, but it will be something that can happen in many years.

Lastly, then, there are contaminations like if the milk has a hybrid material load. Sometimes people add things like hydrogen peroxide to the milk to kill the bacteria. So these kinds of contaminations in high doses are harmful.

How do you leverage technology to ascertain the quality of milk? And how do you involve farmers in the quality certification process?

We as Bio Foods do 17 tests. So when the milk is collected, the milk tank is sealed. When it arrives at Bio Foods, the seals are broken and we take a sample and 17 tests are performed.

The milk does not enter the factory until all 17 tests are passed. If there's any parameter that is not met, the milk is not accepted and will be rejected. So, we have that test capability.

We're now working together with cooperatives to help them do the same test at their level so that they can start testing the milk from farmers to establish whether the milk is good or not. So, if there's a problem, we don't just say it's rejected, we go to the farm to see where the contamination happened.

How many farmers are you currently working with?

We are currently working with about 30 mixed-to-large farms and about 1,500 smallholder farmers. Before we started taking milk from the cooperative, we did a whole plan with the cooperative and the cooperative did a lot of training with their farmers to make them ready for quality-based pricing.

We started doing a lot of training for the farmers. If the farmer currently gets Sh35, when they work with Bio Foods, they get Sh45 or Sh50. That's sh15 more per day for three litres. If we then help them to increase maybe two litres to five litres and because the cow has the potential to give 20 and let's make it five, that means the farmer's income will go up by about Sh150,000 a year per cow. That's more than Sh10,000 per cow per month. Can you imagine? What an incentive and what an impact that has on the farmer. So it's a win-win.

What are some of the challenges facing milk farmers, and how are you helping to address them?

I think farmers are people we need to really admire because there are so many things stacked against them. There's feed which is contaminated, and then there is the weather. When, for instance, we get milk that is too high in aflatoxin, we don't necessarily point fingers at the farmer, we understand.

We do a lot of work with feed producers to make sure that they actually produce consistently safe feeds. So the challenges are weather patterns. Obviously, sometimes we have a lot of rain. Sometimes we have drought, which is difficult for the farmers and difficult for us.

Another thing we do is we pay the same price throughout the year. We do not fluctuate. So when there's a drought and the milk price goes up, we keep the same price, but when the rain comes and the milk price drops significantly, we keep the same price.

How is the cost of animal feeds affecting the dairy ecosystem in Kenya?

At the moment, the input costs in Kenya are high. What we’re doing about that is we have started the pilot together with Pearl Dairy on full production of feeds. We have made a long-term commitment as Bio Foods to start working with other partners on how we can bring the cost of feed down by increasing production per acre.

We are also trying to experiment with different types of grass to see if we can produce feeds and flora, which are at the same nutritional level but at a lower cost. In order for the Kenyan dairy sector to become competitive, and to be able to export, we need to make sure that the cost of feed goes down.

That's a key area for us, and we see the main thing that we need to achieve as a nation is that the average production per hectare actually goes up. There're areas in Kenya that produce systems with zero irrigation in medium rainfall areas. A lot more is possible, through rotational cropping, regenerative farming, zero tilling and so on.

One of the key things that we're also working together with this administration is focused on is how we, in the longer term, bring agricultural productivity up.

What interventions should the government make to spur the dairy sector?

Currently, there’re some structural changes being made, which are necessary. So as a company, we are supportive of the fact that that we have, for instance, fuel subsidies.

In principle, we are supportive of the difficult changes that are being made. I think where we see a challenge is predictability. As for the manufacturing sector, and the dairy sector in general, with every Finance Bill, we need to ask ourselves what is going to happen now. That is a bit challenging.

But in principle, we understand the necessity that some structural changes need to be made. And we're supportive of that. I think the most important thing is predictability. Let's get it over with and then start building the dairy sector. Let's start building the agricultural sector and start building the manufacturing sector.