Nehruji Baiji has run the family shop on Moi Avenue for 10 years, dealing in clothing and executive bags.

Now in the hands of the family’s third generation, the shop has been a major source of income, adding to other businesses in other parts of the city, including Parklands.

Business was good in the 80s and 90s, Baiji says, when buyers spent on new clothes and accessories, which drove local businesses and the cotton textile and apparel value chain.

Today, sales have dropped by more than 40 per cent amid high operating costs and cheaper imports by stall operators and second-hand clothes, posing a major threat to business.

While sales could hit Sh700,000 per month some years back, currently, he makes just about Sh450,000 per month.

“If you take out Sh100,000 rent, salaries, restocking and other utility bills, the profit is marginal,” Baiji told the Star.

The business also pays about Sh50,000 for trading licence, fire certificate (Sh6,000) and pest control certificate (Sh1,500), totalling Sh57,500 annually.

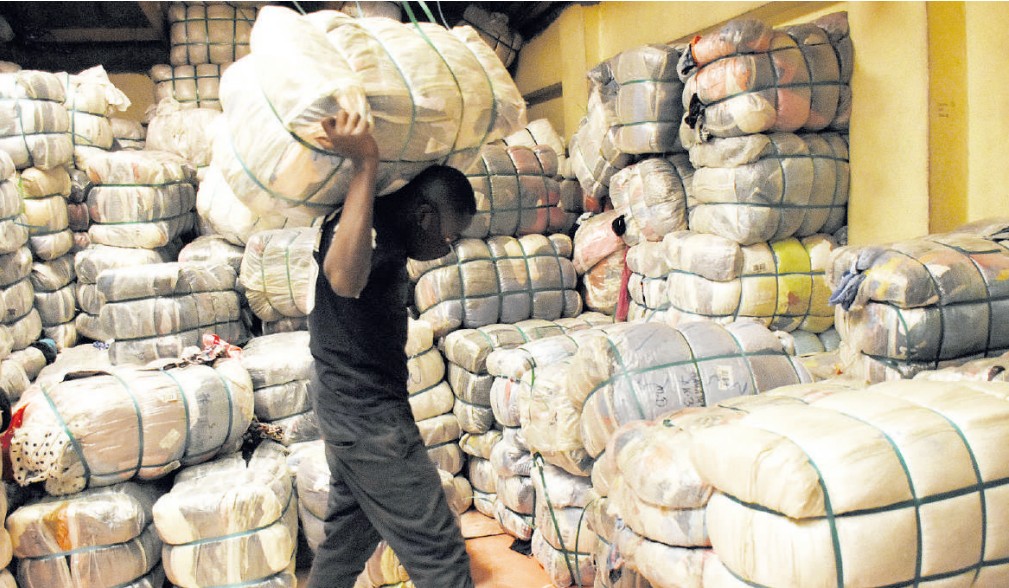

Meanwhile, William Mogaka has been hawking second-hand clothes (mitumba) in Nairobi’s CBD at no cost, with his only expenditure being the Sh3,000 he spends in the morning to get his day’s stock at Gikomba market.

That was until the county government ejected hawkers from the city’s main streets last month, which put a smile on the face of the likes of Baiji.

“They are a menace,” he said.

“Can you imagine you are paying rent, licences, taxes, utility bills and someone comes to block your shop with their wares set just outside your door? It does not make any business sense for the shop owner.”

Catherine Wamahiu operates a mitumba depot near City Stadium in Nairobi.

She has been in the wholesale business for 10 years, and on average, she makes a profit of up to Sh200,000 per month.

She says bales with assorted women clothing go for between Sh20,000 and Sh25,000.

Ladies’ handbags bales range between Sh14,000 and Sh18,000, while those with men outfits can go for up to Sh40,000.

“This business has helped me fendfor my family and meet other expenses, including educating my children,” she told the Star.

She imports from China and collects her stock at the Port of Mombasa, which is delivered by trucks to Nairobi.

This is the paradox of Kenya’s textile and apparel industry, which has over the past two decades favoured foreign markets both for raw material imports and export of finished goods, as the local value chain struggles.

Public policy expert Anthony Mwangi, who is the former Kenya Association of Manufacturers CEO, says interestingly, Kenya is one of the global suppliers of big fashion brands in America.

In fact, Kenya is the largest exporter of garments under the African Growth and Opportunity Act programme, manufacturing for big names such as H&M, Levi’s, JC Penny, Wrangler and Otto, among others.

“Despite the local sector making a mark in the global space through our apparel exports, accounting for about Sh51 billion, our imports remain high. This shows an urgent need to reinvigorate the sector,” Mwangi said.

INDUSTRY HISTORY

Back in the 80s and 90s, Kenya had a strong fibre to fashion industry, with strong downstream developments, including ginning, spinning, weaving, knitting, dyeing and finishing and garment making facilities both for local and export markets.

The country had about 52 textilemills at its peak in 1984, and half a million-garment workers.

Today, there are only four key large mills and 54,000 employees in the entire value chain, according to official government data.

Farmers stopped planting cotton in the late 90s because of poor prices from the once key cash crop and Kenya’s oldest commercial crop, which fed thousands of families, choking off supply of raw materials.

Industry PS, Juma Mukhwana says Kenya once thrived as a dominant player in the cotton, textile and apparel value chain, and stood as a leading foreign exchange earner.

“However, the sector collapsed due to trade liberalisation and the subsequent introduction of second-hand clothes,” he said in a National Cotton Textile and Apparel Policy paper.

Industry players say Kenya’s textile industry is struggling primarily due to the overwhelming influx of cheap, second-hand clothing (mitumba) from overseas, which significantly undercuts local production, coupled with issues like high production costs, inadequate infrastructure, limited access to financing and a lack of robust policies to support the sector.

This has led to factory closures, job losses and a decline in domestic cotton production.

Kenya banned mitumba in the mid-1960s to protect the local industry, eased the ban in the mid-1980s to allow donations to refugees, and lifted it altogether in the early 1990s as world markets liberalised.

Some notable Kenyan textile factories, among them Kisumu Cot-ton Mills and Mount Kenya Textile Mills, went down due to financial difficulties and competition from cheap imported textiles and the removal of price controls.

Eldoret-based textile manufacturer Rivatex, once a giant manufacturer in the country, also deteriorated.

The government has injected more than Sh7 billion into modernisation of the state-owned textile mill, which employs more than 1,200 people, with another 10,000 people benefitting indirectly through the cotton industry with support from donors.

While the company has expanded its spinning, chemical store and finished goods departments, it is still struggling to secure raw material as a result of low or near-zero local production.

“We must have a reliable source of raw materials. Rivatex needs 200,000 acres for cotton growing to end shortage,” management said.

The firm requires more than 36,000 bales of cotton or 7.2 million kilos of cotton annually, but does not get even half the amount.

JOBS AND REVENUE

Jobs in the entire value chain have declined from a high of 500,000 in the 90s to a mere 20, 000 direct jobs in the textile industry, save for the value chain.

“The textile mills, once a stronghold of the sector, now face hurdles such as outdated machinery, high production costs and heavy competition from imported textiles and second-hand clothing,” PS Mukhwana said.

“Additionally, while Kenya’s apparel industry is dynamic, it grapples with issues in quality, branding and market access.”

While it remains among the biggest beneficiaries of the African Growth and Opportunity Act with exports to the US, the sector is lying on its deathbed when it comes to the local market as mitumba dominates wardrobes in many Kenyan homes.

According to a recent report by the Observatory of Economic Complexity, Kenya had an average annual import bill of $203 million (Sh26.3 billion) in 2022 for second-hand clothes, the biggest in Africa.

It was followed by Ghana at $165.4 million (Sh21.4 billion), Tanzania $150 million (Sh19.4 billion), Angola $120 million (Sh15.5 billion), Nigeria $95 million (Sh12.3 billion) and Cameroon $94 million (Sh12.2 billion).

The State Department for Industry puts the value of Kenya’s annual imports for second-hand clothing and shoes at an average Sh400 billion.

A survey by the Institute of Economic Affairs shows Kenya’s used clothing imports come mainly from the US, the UK and China.

A visit to Gikomba and Toi open air markets in Nairobi, Kongowea in Mombasa and Kibuye in Kisumu show that the country is big on second-hand clothing, with the markets being the landing base for imports from international markets.

China is Kenya’s top import source for mitumba, according to the United Nations, followed by Pakistan, Canada, the UK, the US, Poland, UAE, Germany and India, with the Republic of Korea closing the top 10 list.

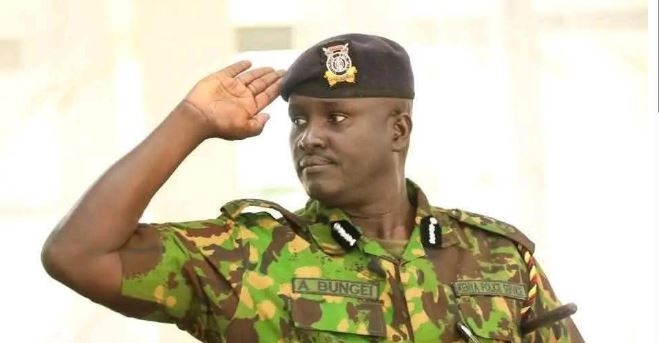

In 2016, the presidents of Burundi, Kenya, Rwanda, Tanzania and Uganda resolved to ban the import of mitumba from 2019 to develop their domestic industries.

Kenya withdrew in 2017 after the US threatened to end its duty-free and quota-free exports to the American market under AGOA.

It is estimated that the mitumba sector contributes at least Sh1 billion in revenue per month.

Apart from that, the businesses offer livelihoods to almost two million people, according to the Mitumba Consortium Association of Kenya, which represents second-hand clothes dealers.

Employment covers importation, handling, alterations and refinements and distribution of clothing.

MCAK has since called for a balance between the local textile industry and importation of second-hand clothes.

MCAK chairperson Teresia Wairimu says Kenya’s low- to middle-income consumers predominantly buy second-hand clothes.

“Kenya should bank on this high population and build a cluster of textile producers who, together with second-hand clothing operators, would create capacity for long-term innovation and growth,” Wairimu said.

An industry report by the Institute of Economic Affairs indicates 91.5 per cent of households buy second-hand clothes worth Sh1,000 and below, with a paltry 8.5 per cent buying clothes worth Sh1,000 and above.

“The existence of second-hand clothes is a demand-side issue rather than a supply-side issue,” IEA noted in its report.

“For a considerable number of people, incomes in the country can only support the buying of second-hand clothes.”

Affordability, uniqueness and durability compared to local fabrics also makes the clothes popular.

GOVERNMENT INTERVENTION

The government is banking on the National Cotton Textile and Apparel Policy to revive the local textile industry.

It is also pushing for the uptake of locally produced textiles and apparel under the ‘Buy Kenya Build Kenya’ initiative.

According to the State Department for Industry, the policy aims to revitalise Kenya’s cotton, textile and apparel sector by addressing key challenges that have contributed to its decline.

To increase cotton production, the government has introduced certi ed cotton seed systems, approved the commercialisation of Bt cotton in 2019, and is undertaking research at improving cotton varieties, agronomic practices and processing technologies.